The history of Bangladesh’s Ready-made Garments (RMG) sector goes back to the 1980s when Bangladesh was a war-ravaged nation. Then, the late Nurool Quader Khan took the initiative to send 130 workers to South Korea to train in producing ready-made garments.

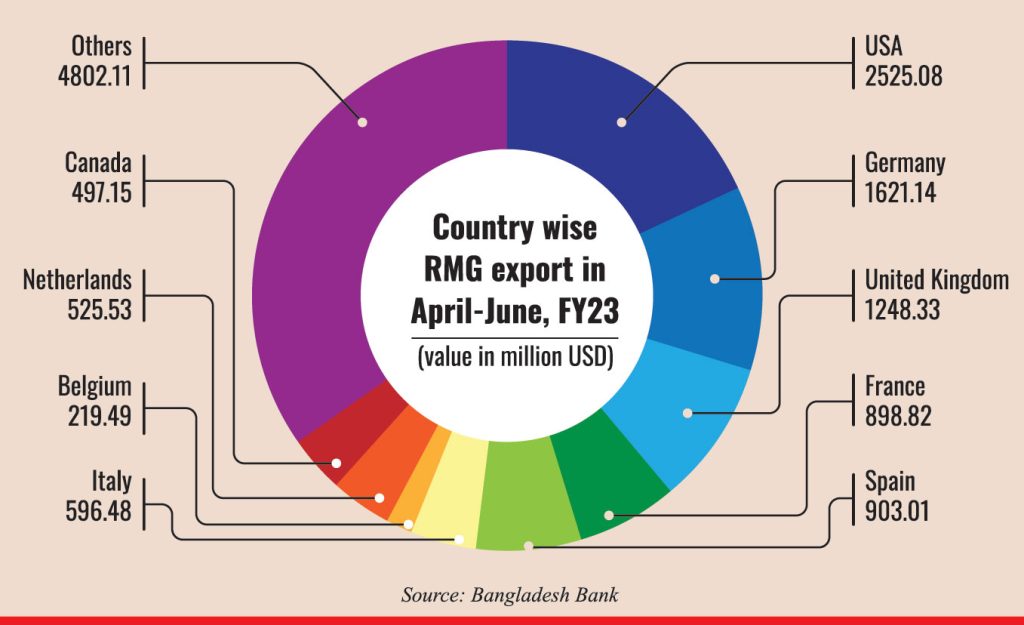

Following this, several other notable names, such as the late Akhter Mohammad Musa of Bond Garments, the late Mohammad Reazuddin of Reaz Garments, and Md Humayun of Paris Garments joined the RMG sector and further contributed to it. Since then, the RMG sector has continued to contribute around 10% to the economy of Bangladesh. The export earnings from the RMG sector stood at USD 11.73 billion in April-June of FY23. Though the figure is higher than that of the same quarter of last year, it continues to be 4.22% lower than the previous quarter.

LDC graduation

Bangladesh was included in the Least Developed Countries (LDC) group in December 1975. After 50 years of its inclusion, it is on its way to graduating from the LDC group in November 2026. The graduation is determined based on three criteria: GNI Per Capita, Human Asset Index, and Economic Vulnerability Index. As much as this is a matter of pride for the country and its people, Bangladesh is also expected to face certain challenges post-graduation due to the loss of preferential treatment. The most significant preferential treatment that Bangladesh receives is the duty-free and quota-free access of 70% of its exports. As a part of the LDC, Bangladesh enjoys preferential treatment through greater market access, flexibility in commitments, waivers from obligations, a longer implementation window for agreement-specific disciplines, and aid for trade, which will no longer be available once it graduates. The benefits from LDC-specific International Support Measures (ISMs) will also be removed.

Sustainable measures in the RMG sector

RMG is the biggest contributor to the carbon footprint of Bangladesh. About 0.57 million tonnes of waste are produced annually by the RMG sector, of which two-thirds are exported. Taking sustainable measures and recycling all the cotton waste could save around USD 500 million annually. Groundwater pollution, airborne waste, dust and noise, soil degradation, greenhouse gas emissions, and rainforest degradation are some forms of environmental degradation caused by textile waste. The clothing and textile industry is responsible for 4% of the global carbon emissions, making it an absolute priority to incorporate sustainable measures in production techniques.

Current status of sustainability in RMG

We can observe a shift in the consumer mindset regarding sustainable fashion. Customers are now more than willing to pay higher prices for sustainable fashion. A consumer mustn’t feel guilty about wearing clothing that might have contributed to worsening the environmental conditions. Customers no longer want to remain passive while the planet is undergoing massive environmental degradation. Therefore, for the brands, even from a business and CSR perspective, it is also a tool for branding and marketing. For example, by 2040, Marks and Spencer want to achieve net zero by reducing GHG emission and carbon footprint. Brands like H&M, Zara, Puma, and Adidas have set sustainability goals.

Mr. Imtiaz Reza Sohan, working for Marks and Spencer for five years now, commented on this matter,

“When it comes to using polyester, the industry has started using recycled polyester, and for cotton, the industry has started using organic cotton and BCI cotton, which are sustainable forms of cotton. The recycled polyester is certified by governing bodies, and many brands are sourcing the polyester from thrown away bottles collected from the sea.”

“One pair of jeans requires as much as 10,000 liters of water. There is now technology that reduces water consumption by up to 90%. Also, brands are promoting sustainable fashion. As for M&S, they sell garments they feel would sustain up to 20 washes. In factories, plants (ETP and WTP) purify the used water for dyeing and finishing into drinkable water.”

Industry Insider talked to Mr. Nafiun Bin Sharif Sufal, an Auditor of OEKO-TEX® STeP (Sustainable Textile and Leather Production) at Hohenstein Institute Bangladesh. He remarked, “Oeko-tex provides certification in Bangladesh. It evaluates the process in 6 different ways: Chemical contribution, environmental performance, social, safety, quality management system, and environmental management system. It then generates a report based on the evaluation, and a certificate is provided, including the scoring. A ‘Made in Green’ label is provided for all products which pass the evaluation.’

Benefits gained due to sustainability

Certain insights were also gained from Mr. Ikramul Hoque Rayan, currently the Head of Supply Chain Management at Plummy Fashions Ltd. He raised concerns regarding the lack of a proper system to ensure fair pricing from buyers for sustainable products.

“The current state of the RMG sector is the worst in the last 12 years, especially after the Russia-Ukraine war. When the sustainable factories opened, there was high encouragement from the buyers, but later on, the buyers refused to pay higher prices for the sustainable products. Buyers are unwilling to pay more; however, they sell sustainable products at higher prices to the end consumer and retail shops.”

He further explained, “The construction equipment, solar-based power equipment for sustainable measures are costly to maintain, and without higher prices, it will be difficult to continue. Most factory owners are afraid of raising the concern of charging higher prices due to the fear of losing out on business. Since sustainable establishments are costly, it is also impossible to shift back to traditional practices.”

As a part of its sustainable measures, Plummy Fashions has 70% open area for greeneries and oxygen supply. No multi-storied buildings exist, and 70% of the power is used from solar panels. There is a water treatment plant to reuse and clean the water. The yarn used is also made from recyclable cotton.

Possible assistance from the government

Regarding the assistance provided by the Government, Mr. Sohan shared,

“85% of the export earnings of Bangladesh comes from the RMG industry. So, if it collapses, Bangladesh’s entire economy will collapse. To cover up the initial turbulence after graduating from LDC, the government is trying to extend duty-free access and GSP for at least five more years after graduation. The government is facilitating the industry through EPZs and incentives. 100 Special economic zones are in the process of being started.”

“Due to the economic growth, the expected wages might be too high, removing the price competitiveness that Bangladeshi products enjoy now. If the price competitiveness is not there, factories might think about shifting their operations to other regions in the future where the cost will remain lower.”

Retaining the benefits

Mr. Rayan suggested that it is not the LDC graduation that the RMG sector should be worried about. Instead, it should focus on obtaining fair prices from buyers. Regarding the future roadmap for the RMG sector, he proposed,

“LDC effects will not be much as most factories are self-sustainable. However, it is imperative to sit in a dialogue to raise the concerns on behalf of the RMG sector. The main concern is not LDC graduation but rather lower prices from buyers. There is also inefficiency in the RMG sector due to the lack of quality human resources.”

He believes that RMG needs more training facilities and the traditional educational methods need to impart knowledge relevant to the RMG sector. Unlike China, Bangladesh does not have developed workers, so it could not grow as much despite having cheap labor costs.

The lack of proper pricing was also further emphasized by Mr. Sufal, who mentioned that the merchandisers are not united and are being exploited. There is a lack of proper negotiation from the merchandisers’ end; hence, they cannot sell at a higher price.

He further explained, “RMG sector in Bangladesh needs to advance towards producing value-added and technical products such as protective gears or aesthetic garments. There is also a huge need for investing in R&D to support the complex fabrication processes.”

He also emphasized the need for government initiatives in providing sustainable finance. The availability of easier and cheaper loans will make it easier for factory owners to further incorporate sustainability measures within their production process.

Shehrin is a business enthusiast who loves journaling and taking random pictures in her free time.