The label ‘Made in Bangladesh’ may have been seen on products purchased abroad, especially RMG products. A global effect is being made by various industries, not just the RMG (Ready Made Garment) manufacturing sector. Nonetheless, their local popularity hasn’t grown as many global brands like Zara, Gucci, or Armani.

From the world’s point of view, Bangladesh’s image is still limited to a nation that can make your products ready at a lower labor cost. And this is certainly not an ideal image. However, do we know Bangladesh can build brands of its own? Do we know how the country can make a journey from a mere order-maker to a game player?

On growth trajectory

Analyzing the exports year by year can give us a clear picture of how good the numbers are. Bangladesh’s total export earnings from July 2022 to February 2023 were above USD 37 million, compared to USD 33.8 million in the previous year, as per Export Promotion Burea (EPB) data.

A similar kind of growth is seen in the country’s leather and leather products. From July to February FY22, Bangladesh earned USD 784.98 million from leather and leather products, which grew by 6.04% in FY23 to USD 832.38 million. Exporting commodities like cement, salt, stone, and petroleum, Bangladesh earned USD 36.14 billion in the same period in FY23, with a year-on-year growth of USD 4 billion.

Despite having challenges, the country is still performing well. The nation’s industrial culture must comply with international norms to entice more foreign firms to open operations here and increase its global market presence. Perhaps fostering a ‘Cultural of Reliability’ is one of the essential components.

Why practice the culture of reliability?

According to a research paper titled ‘Achieving Product Reliability: A Key to Business Success,’ Samsung recalled 2.5 million Galaxy Note 7 devices in September 2016 in response to allegations of numerous phones catching fire due to defective batteries. Investigations revealed that a mix of poor design and manufacturing defects was to blame.

This is an example of reliability failure. Although many other reliability failures go unnoticed and do not have catastrophic effects, they cause customers significant inconvenience. The preference for reliability conveys a clear message to manufacturers who want to build a customer base.

On the other hand, reliability has many crucial advantages, such as increased plant uptime (uninterrupted production time), optimal production that reduces production loss and ensures process, human, and environmental safety, and more maintainable, reliable, and available assets, and lower maintenance and operation costs.

What is a reliability problem?

Both ‘failure avoidance’ and ‘quality through time’ are colloquial terms for reliability. When a product consistently fails to fulfill its intended purpose in the eyes of the customer, this is referred to as an eld reliability problem. Establishing a reliability culture can solve the problem above.

For industry insiders, practicing reliability and establishing a reliability culture may be the ideal way to meet those problems. Monitoring important equipment data and taking appropriate action might be a straightforward example of decreasing downtime through reliability.

Even in firms that placed a high priority on quality, reliability assurance used to be an afterthought often. It’s also known as the Design-Build-Test-Fix cycle — meaning that producers worked to identify and address reliability issues through in-depth testing after the production.

Forward-thinking companies and industry leaders have realized the high cost of ensuring reliability through reactive tactics. A proactive ‘get it right the first time’ mindset has thus replaced the conventional Design-Build-Test-Fix approach. Receiving early warnings about high vibration, low or high differential pressure, high differential temperature, instability, clogged suction filters, and control vane defects will help prevent unexpected compressor outages in the case of a plant where the compressor is an essential component. Preventive maintenance measures will also help.

Developing a proactive reliability culture

A few straightforward initiatives can be used to develop a reliability-centered culture. Firstly ensure accountability at the executive level and delegate it down. Determining the root cause of critical equipment failures and ensuring that fundamental preventative maintenance procedures are followed. Next, start detecting harmful elements (equipment that causes the repetitive breakdown of the production process). Also, improve equipment and process and consciousness of the workers.

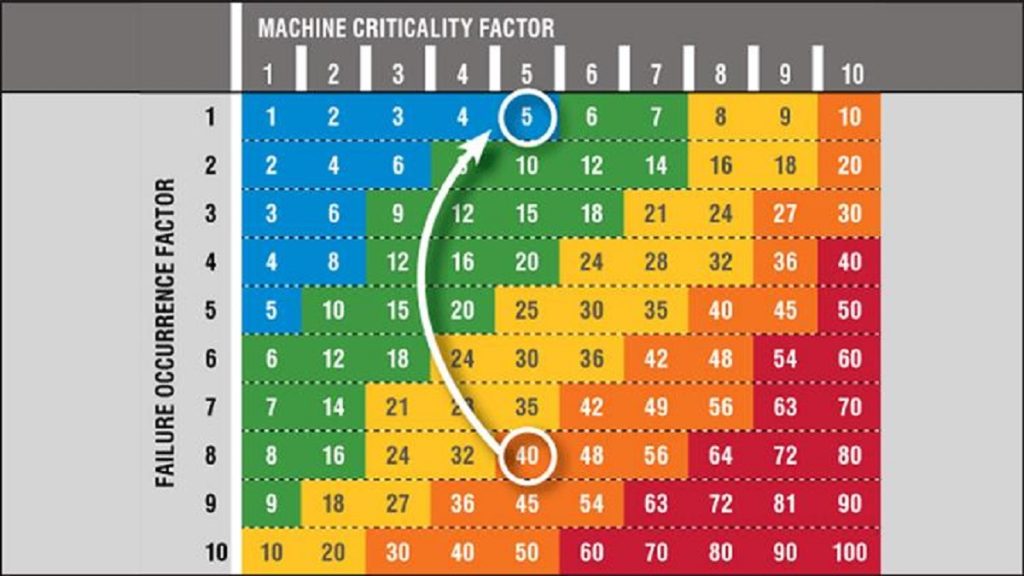

More advanced reliability practices, such as evaluating equipment criticality, asset integrity management, strategic Enterprise Asset Management (EAM) plans, competency management plans, and so on, can be implemented once the organization has successfully implemented these first-tier initiatives. Other analytical techniques like FMECA (Failure Mode Effect and Criticality Analysis), FTA (Fault Tree Analysis), and RCM (Reliability Centered Maintenance) can be integrated.

A few decades ago, Vietnam, China, Malaysia, Indonesia and Thailand — all experienced similar circumstances. But, these nations implemented the correct industrial and national policies at the right time, providing a trampoline for their success. Executives in our sector must foresee both the short- and long-term benefits of instilling a reliability-centric culture within their firms.

To deal with a world transitioning to Industry 5.0, the government should take steps to encourage industry adoption of a reliability culture and may initially give little incentives.